- Our Services

- Industries

- Automotive Materials and Components

- Electronic and electrical

- Ship

- Industrial detection

- Environmental detection

- Service

- Test

- Foreign Material Analysis-Formulation Analysis

- Authentication

- Train

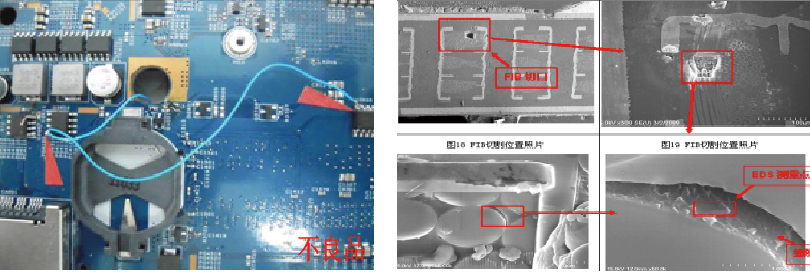

- Failure analysis

- Laboratory Technical Services

- Judicial expertise

- Insurance technology appraisal

- Price evaluation

-

Our Services

Upgrade the quality level of Made in China

-

Resource Center

-

Test application form

For testing requirements, please download the test application form

-

FALAB People

Falab people become what you want!

-

-

News

-

Company News

Get the latest business news

-

Industry Information

Deliver the latest information and analyze the industry hot spots

-

-

Join Us

-

Recruitment

Falab, welcome to join us.

-

-

About FALAB

-

FALAB Introduction

China's third party testing and certification services pioneer and leader

-

Culture

To contribute to the quality and technology improvement of China's manufacturing industry

-